Process improvement and lead time reduction

Consistently and continually providing rapid and effective customer service, Right First Time.

Making end-to-end processes visible in order to identify errors, quality problems, variability and waste.

A process is a series of connected activities that consist in transforming incomings into outgoings to satisfy a customer. Good management of your processes is governed by the identification of each player’s roles, resources and activity rules in order to improve process efficiency.

A stable process is governed by an understanding of each player’s role and responsibility and the resources and task sequence necessary to get the job done.

But, as long as customers continue to demand ever faster delivery, even higher quality, and the absolute lowest possible price, organizations require more than just process stability to be competitive To continually satisfy this challenge, it is necessary to have processes that are adaptable both in terms of design and execution.

Therefore, we need processes that are both stable and designed to be continuously improved. The key to fulfilling this objective is to make your processes – from end to end – visible. Process visibility allows us to continually monitor and measure process output. Once a process can be measured, it can be improved.

We can help you identify and improve your process value streams. Using both Voice of the Customer (VOC) and Lean Six Sigma approaches, we will gather and analyze all upstream and downstream information necessary identify process inefficiencies. Then, working in partnership with you, we will develop a Lean plan to eliminate all non-value adding activities.

From a traditional culture to a Lean way of working.

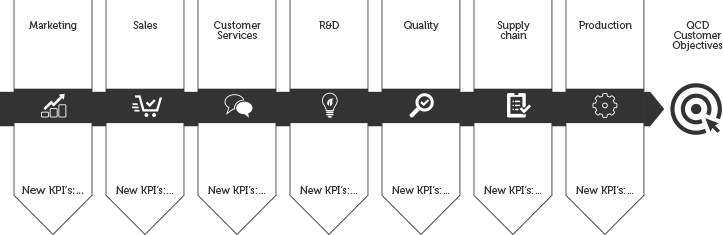

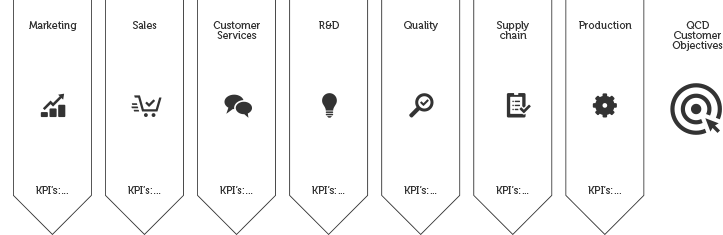

From silos…

…to a cross functional customer-oriented Value Stream.