Applying lean thinking outside the manufacturing environment can bring big returns to your organization.

Recently, we employed lean techniques to assist an organization with a major capital project—our mission, finding 30% more capacity within their existing facility. Here’s a snapshot of the engagement.

The Company

A brand-named fast-moving consumer products manufacturer located in North America. The company operates several manufacturing campuses and holds a dominant market share in their market. Their products are sold under many national and retail brands. The company’s business strategy involves pursuing aggressive sales growth and cost reduction.

The Case Backstory

Productivity Inc. consultant, Jim Vatalaro was working with the plant manager at one of the business’ smaller manufacturing campuses. The improvement goals were to achieve both a sustainable business impact and build meaningful internal improvement capabilities.

Over the course of 8-months Jim and the plant manager collaborated in the implementation of selected lean tools including Value Stream Mapping, 5S, changeover reduction and standard work. In the process, they worked together to introduce the site employee community to a systemic approach to lean improvement. This effort helped the facility realize a 75% reduction in changeover times and a productivity improvement of 50%. With a solid understanding of value stream mapping, the facility associates now understood how to determine the most advantageous areas in which to focus their ongoing improvement efforts.

Over the course of their implementation, a strong and collaborative working relationship was developed so when the plant manager was promoted to director of operations at the business’ largest production campus, he asked Vatalaro to continue their partnership. One of their first projects together was the execution of a major consolidation effort that required his facility to find 30% more capacity in the existing facility. The project timeline was 12 weeks.

The project’s “bold goals” included the following:

A. Rapidly create 30% organic capacity to enable…

- a. Permanent closing of one of the company’s mid-Atlantic manufacturing campuses

- b. Identify and transfer all required assets and products within existing space

- c. Absorb the additional workload without adding new associates

B. Identify and implement the required management system improvements to assure long-term sustainability. This included developing a flexible electronic capacity model that fully explains throughput and the impact of specific waste variables on the constraint processes

C. Developing an internal ability to refresh the capacity model plus the ability to adapt the capacity model as the production processes/product mix evolve over time

D. Engaging with campus leadership team to teach them how to effectively manage the new material and information flows

Over the course of the 12-week project timeline, a 3-person project team, working with Vatalaro, performed the following activities:

- Using value stream mapping (current state) and gemba walks, they

observed, documented, and analyzed both campus’ operations and assets. - The team then conducted a detailed product demand and flow study for both campuses. They ranked 1,500 product SKU’s (by descending volume) to uncover the 20% that drove 80% of demand.

- Using data discovered in the ranking exercise, the team then explored Processes alternatives to product family definitions. Once product families were re-defined, detailed current state material and information flow diagrams for each identified product family were created.

- The next step had the team research alternative “asset chain” groupings and identify constraint and sub-optimization points. They then developed several alternative future state detail design concepts

that supported the project’s bold goals. - The team then developed a Lean Scorecard specifying 14 criteria and and TPM event applied a new capacity model to predict throughputs. They ran each catalog. design concept through an evaluation (rooted in lean principles) and then simulated the most promising value stream design concepts.

- A detailed design recommendation, associated logic, and business case were drawn up that specified which products were in which product families and which asset chains these products needed to flow through. Disconnections requirements were also identified.

- Using data uncovered during the project, the team created a new “capital plan” outlining the equipment that would be needed (over the next several years) to align to their recommended solution

- At the end of the project, a formal report was created outlining the recommended solution to the client leadership team who had been kept apprised of progress throughout the project.

- Once approved, value stream managers were identified and trained, the capital plan was reset, sub-optimal process connections were disconnected and new flows were energized, and the lines/product transitioned into the facility.

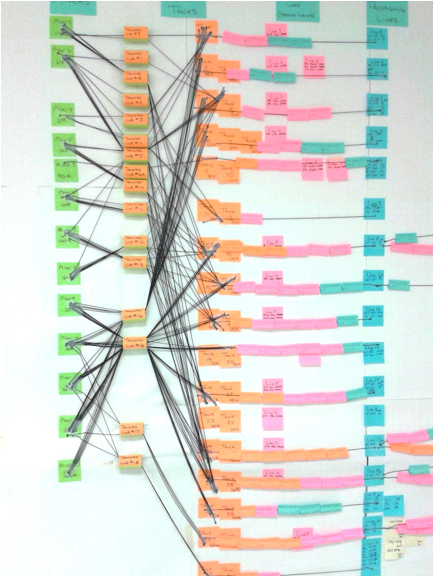

Exhibit “A”

A photo of the visual display showing the “flows” for the 20% of the SKU’s that drove 80% of the volume.

The Results

All project bold goals were met along with one unanticipated outcome:

- The targeted 30% organic capacity increase was exceeded

- The mid-Atlantic campus was closed and the required assets were transferred within the receiving facility foot-print

- Product family groups and specific product families were defined

- The business was redesigned around the concept of the value stream

- Asset chains were optimally defined for each value stream

- Every product in the 1500+ SKU count had a clear asset chain that would be followed in its production

- Many process connection points were decoupled preventing sub-optimal asset selection

- A completely new understanding of the true nature of future capital improvements was gained

- Value Stream Managers were “developed” and deployed to manage end-to-end customer value creation

- The client’s “Value Stream Operating Model” was built and deployed

- …and, the one unanticipated outcome, the director of operations was promoted to site vice-president. A coincidence? We don’t think so!

In the example above, a prescriptive (as opposed to process) consulting approach was applied. Elements of 3P (Production Preparation Process), were employed and an Oobeya room constructed. The project team worked with other facility resources to run simulations on their various future state design concepts.

Lean thinking can be applied to all types of projects outside the scope of the typical manufacturing environment. We went on to assist this organization with:

- Pattern production system implementation

- Warehouse visual management and metrics implementation

- Warehouse space productivity improvement projects

- Process Confirmation (an improvement sustaining capability)

- Corporate process mapping support

So, when thinking about your capital projects…think Lean!

This was an exciting project with an impactful outcome for our client. It was great working with and facilitating the team through the process of discovery through to their successful outcome. If you’d like to learn more about this case, or talk about a burning platform(s) in your organization, contact me at my email. I’d appreciate the opportunity to share perspectives.

Jim Vatalaro, Consultant, Productivity Inc.

ASK THE CONSULTANTS

Q. We are a mid-size, multi-plant, consumer goods company that has been utilizing lean tools for about a year. We’ve had a recent change leadership and the new VP of Manufacturing wants to embark on a formalized, system-wide, process improvement effort.

He is looking to Six Sigma, but I don’t want to see our Lean effort end. I know you must have been through this one many times… what’s your advice, which one, Lean or Six Sigma, should lead our improvement program?

A. Lean or Six Sigma, the battle continues… which one will satisfy both the social and technical improvement aspirations and be the most cost effective?

Comparison of Lean and Six Sigma reveal both as change initiatives aimed at reducing or eliminating waste, a primary cause of variance and variability. A fundamental difference between Lean and Six Sigma is that lean is a process and Six Sigma is a methodology. Lean attempts to change organizational culture and solicit behavioral change among employees, whereas Six Sigma solicits employees in the use of scientific methods to solve problems.

One more comparative point… Lean is a continuous and on-going approach under the assumption that change is constant, always creating room for improvement. Six Sigma, on the other hand, is a project-based approach and the project-team disbands on achieving the project’s objectives.

An important note: Lean works by transferring knowledge and building a learning organization system-wide to bring about changes in strategy, structure, and processes. Six Sigma works through the DMAIC (define, measure, analyze, improve, control) methodology using scientific tools of FMEA, ANOVA, DOE and a variety of proven submethodologies suited for statistical analysis and problem resolution.

Lean and Six Sigma, while fundamentally different, nevertheless remain complimentary.

Which one can bring the greatest return to your specific business at the right cost in the desired period of time is all about understanding the strengths and limitations of each concept. In most cases, across all industry sectors, Lean will lead the improvement journey, while concurrently, Six Sigma tackles the more complex technical issues associated with process/product variation and corresponding statistical analysis.